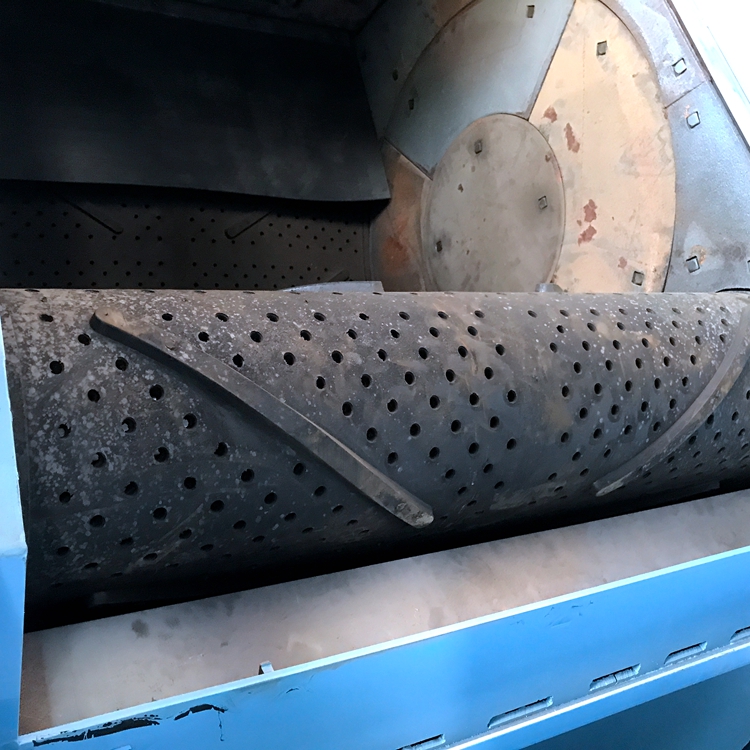

Automatic loading crawler shot blasting machine

Model Q3210

Produtos DETAILS

Automatic loading crawler shot blasting machine

| serial number | project | unit | Q326 | Q3210 | Q3220 | 15GN | 28GN |

| 1 | productivity | t/h | 0.6-1.2 | 2.0-2.5 | 2.0-5.0 | 5.0-8.0 | 12.0-14.0 |

| 2 | feeding amount | kg | 200 | 600 | 1000 | 1350 | 3500 |

| 3 | Piece weight | kg | 10kg | 30kg | 40kg | 250kg | 363kg |

| 4 | End disc diameter | mm | 650 | 1000 | 1200 | 1092 | 1250 |

| 5 | Effective volume | m³ | 0.15 | 0.3 | 0.69 | 0.43 | 0.8 |

| 6 | Shot blasting amount | kg/min | 120 | 250 | 250 | 480 | 350*2 |

| 7 | Dust removal air volume | m³/h | 2000 | 3500 | 7500 | 6000 | 6000 |

| 8 | Power consumption | kw | 12.6 | 24.3 | 50 | 48.5 | 62 |

| 9 | Crawler form | Metal/Rubber | Rubber | Rubber | Rubber | Metal | Metal |

Crawler shot blasting machines are widely used for cleaning metal and non-metal workpieces, including removing surface dirt, oxide layers, rust, as well as pretreatment and surface strengthening before spraying. This equipment is widely used in mass production of parts and product processing due to its excellent cleaning effect and high efficiency. The following are the workpiece types suitable for crawler shot blasting machines:

Casting and forgings: including various iron castings, steel castings and forgings. The crawler shot blasting machine effectively removes oxide scale, sand, rust and welding slag on the surface of castings and improves the surface quality of castings and forgings.

Automobiles and auto parts: Suitable for cleaning engine blocks, crankshafts, gears, brakes, suspension parts and other auto parts to remove surface oxide layers and other contaminants and improve the wear resistance and performance of parts.

Forgings: Used to clean various forging workpieces, remove the oxide layer, dust and impurities produced during the forging process, and improve the surface quality.

Stamping parts: It is suitable for cleaning the oxide layer, oil stains and other surface unclean substances produced during the stamping process, and improving the accuracy and quality of stamping parts.

Gears: Used to clean various types of gears to remove surface grease, rust and other contaminants to improve the transmission efficiency and service life of the gears.

Spring: Clean the oxide scale, dirt, etc. on the surface of the spring to improve the strength and durability of the spring.

Aerospace parts: Suitable for processing aircraft parts, engine parts, turbine blades, etc., to remove surface dirt, oxide layers and coatings, providing high-quality surface quality and corrosion resistance.

Railways and railway parts: Crawler shot blasting machines can be used to clean railway tracks, sleepers, railway wheels, locomotive parts, etc., remove dirt, oxide layers and rust on the surface of railway parts, provide smooth surfaces, and increase fatigue life.

Overall, track-type shot blasting machines play an important role in various manufacturing and repair areas, especially in industrial applications that require extensive cleaning and improving the surface quality of parts. Its efficient shot blasting process makes it an indispensable surface treatment equipment. In terms of technology, manual, mechanical or automatic loading can be selected according to the weight, size, volume and production efficiency of the workpiece to ensure that the workpiece tumbles in the shot blasting chamber and is cleaned and separated through a combination of rubber belts. , bucket elevators and separators. process, ultimately achieving the effect of removing impurities and improving the surface quality of the workpiece.