Support customization of crawler shot blasting machine, professional cleaning shot blasting equipment, stable performance

Model Q3series

Produtos DETAILS

Support customization of crawler shot blasting machine, professional cleaning shot blasting equipment, stable performance

| serial number | project | unit | Q326 | Q3210 | Q3220 | 15GN | 28GN |

| 1 | productivity | t/h | 0.6-1.2 | 2.0-2.5 | 2.0-5.0 | 5.0-8.0 | 12.0-14.0 |

| 2 | feeding amount | kg | 200 | 600 | 1000 | 1350 | 3500 |

| 3 | Piece weight | kg | 10kg | 30kg | 40kg | 250kg | 363kg |

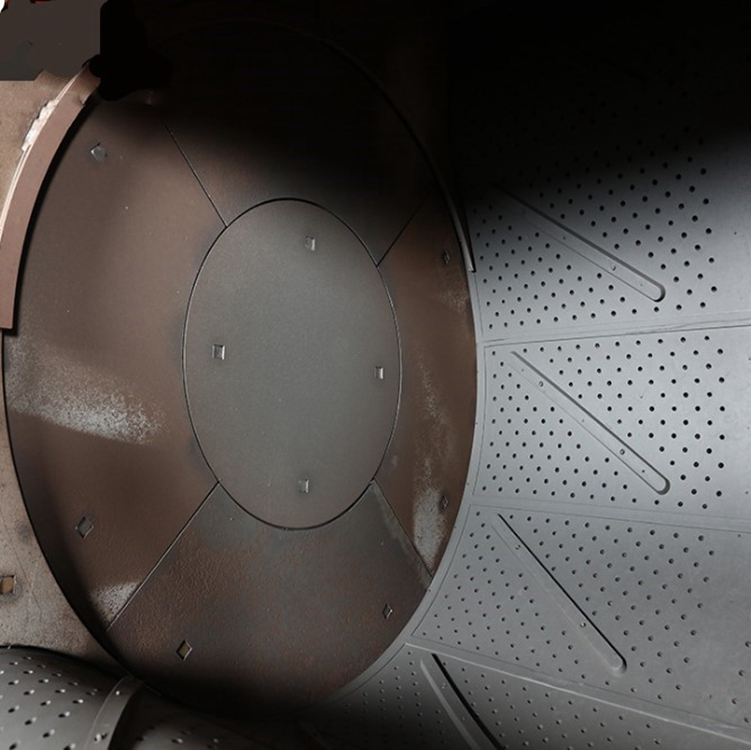

| 4 | End disc diameter | mm | 650 | 1000 | 1200 | 1092 | 1250 |

| 5 | Effective volume | m³ | 0.15 | 0.3 | 0.69 | 0.43 | 0.8 |

| 6 | Shot blasting amount | kg/min | 120 | 250 | 250 | 480 | 350*2 |

| 7 | Dust removal air volume | m³/h | 2000 | 3500 | 7500 | 6000 | 6000 |

| 8 | Power consumption | kw | 12.6 | 24.3 | 50 | 48.5 | 62 |

| 9 | Crawler form | Metal/Rubber | Rubber | Rubber | Rubber | Metal | Metal |

Please select the shot blasting machine model you need and we will give you a quote. If you need to customize special sizes, please communicate with us to get the plan and price. Looking forward to communicating with you, this will be a great start.

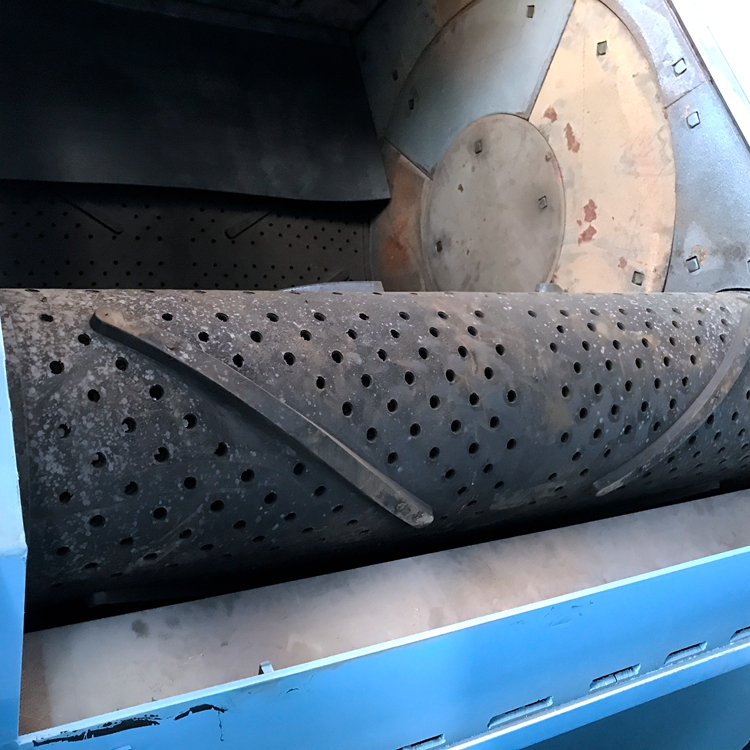

Working principle: Add a specified number of workpieces to the cleaning room. After the machine is started, the workpieces are driven by the roller and begin to turn over. At the same time, the projectiles ejected at high speed form pill-lines, and hit on the surface of the workpiece evenly, thereby cleaning them. , the purpose of strengthening. The thrown projectiles and sand particles flow into the elevator through the small holes on the rubber track, and are lifted by the elevator to the separator for separation. The dust is sucked by the fan to the dust collector for filtration, and the clean air is discharged into the atmosphere. The dust on the cloth bag is mechanically vibrated and falls into the dust collecting box at the bottom of the dust collector. The user can clean it regularly. The waste sand flows out from the waste pipe, and the user Can return. The mixture of shot and sand is taken back into the chamber through the reuse pipe, and is reused after being separated by the separator. The clean shot enters the shot blaster through the electromagnetic shot supply gate to hit the workpiece.